Fashion is an ever-evolving industry that thrives on innovation and creativity. It is an art form that allows individuals to express their unique personalities and showcases the latest trends. In recent years, the emergence of custom rapid prototyping has revolutionized the fashion design process, allowing designers to bring their ideas to life faster than ever before. In this blog, we will explore the significance of custom rapid prototyping in fashion design and how it is speeding up style.

What is Custom Rapid Prototyping?

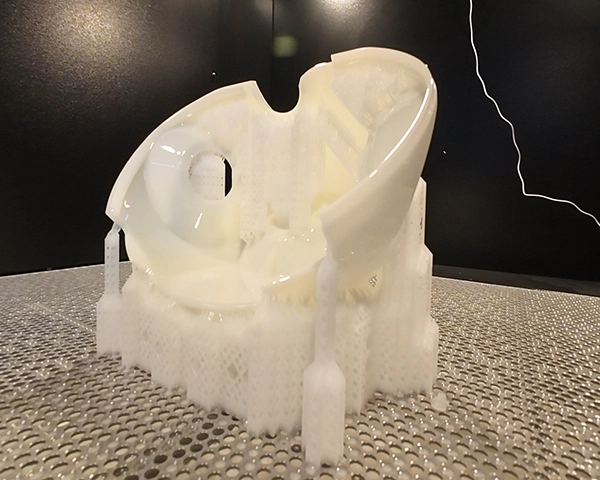

Custom rapid prototyping, also known as 3D printing, is a manufacturing technique that creates three-dimensional objects by layering materials. It enables designers to turn their digital designs into physical prototypes quickly and accurately. Using specialized software, designers can create intricate and complex designs that were once challenging to achieve with traditional manufacturing methods. Custom rapid prototyping has become a game-changer in the world of fashion design, allowing designers to experiment with new styles and materials more efficiently.

Advantages of Custom Rapid Prototyping in Fashion Design

Custom prototyping services offer several advantages for fashion designers. Firstly, it allows for greater design freedom. Designers can easily modify and refine their designs without the limitations of traditional manufacturing techniques. This flexibility enables them to push the boundaries of creativity and explore new possibilities in garment construction.

Secondly, custom rapid prototyping significantly reduces costs associated with traditional manufacturing processes. With 3D printing, designers can avoid expensive molds or cutting dies, saving both time and money. Additionally, the ability to create prototypes quickly and iterate on designs before final production reduces the risk of costly mistakes.

Shortening the Time to Market with Custom Rapid Prototyping

In the fast-paced world of fashion, timing is critical. Custom rapid prototyping allows designers to speed up the production process, ultimately shortening the time it takes for garments to make it to the market. With traditional manufacturing, production timelines can be lengthy due to the time-consuming process of creating molds and waiting for samples. By utilizing custom rapid prototyping, prototype manufacturing companies can iterate designs rapidly, making adjustments in real-time, and reducing time delays.

By embracing custom rapid prototyping, fashion brands can quickly respond to ever-changing consumer demands and stay ahead of their competition. This technology enables them to bring new designs to the market faster, capitalizing on the latest trends and maximizing sales potential.

Embracing Custom Rapid Prototyping for Better Designs

Custom rapid prototyping in fashion design not only speeds up the production process but also enhances the overall quality of designs. Designers can experiment with different materials, textures, and patterns, exploring innovative combinations that were once difficult to achieve. 3D printing allows for intricate detailing and precision, resulting in garments that are impeccably tailored and visually striking.

Moreover, custom rapid prototyping such as cnc 4-axis machining services promotes sustainability in the fashion industry. By producing garments on-demand and reducing the amount of wasted materials, designers can minimize their environmental impact. This shift towards more sustainable practices aligns with the growing demand for eco-conscious fashion and consumers' desire to support brands with ethical production methods.

Custom rapid prototyping has revolutionized the fashion design process, offering designers increased creative freedom, shorter time to market, and better designs. This technology has become a valuable tool for fashion brands looking to stay competitive in the fast-paced industry. As the fashion world continues to evolve, custom rapid prototyping will undoubtedly play an even more significant role in shaping the future of style.

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- How Much Do You Know About The Process -- Vacuum CastingFebruary 27, 2023Why vacuum castingIn our daily life, we often apply to plastic products, in general products, the use of more thermoplastics, this plastic in industrial production, generally with thermoforming, can b...view

- Small Parts, Big Impact: Precision Prototyping Machining in Micro ManufacturingOctober 27, 2023In the realm of manufacturing, precision is the name of the game. Nowhere is this more evident than in micro manufacturing, where the creation of tiny, intricate components is crucial for a wide range...view

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- Benefits of Custom Rapid Prototyping ServicesMarch 19, 2024In today's fast-moving industrial sector, custom rapid prototyping services have become an important tool for many companies to enhance the competitiveness of their products and accelerate the pac...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view