In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. These tools, designed with meticulous attention to detail, contribute to the creation of timepieces that not only measure the passage of time but also embody the pinnacle of mechanical artistry.

The Precision Paradigm: High Precision Tools in Watchmaking Craftsmanship

At the heart of the watchmaking craft lies an unyielding pursuit of precision, and high precision tools are the artisans' trusted companions in achieving this pinnacle of accuracy.

Watch movements, the mechanical hearts of timepieces, demand the utmost precision in their calibration. High precision tools, delicately crafted for the purpose, ensure that each gear, spring, and escapement is perfectly calibrated. This precision is not just about accurate timekeeping but also about preserving the longevity of the timepiece, creating watches that stand the test of time both in accuracy and durability.

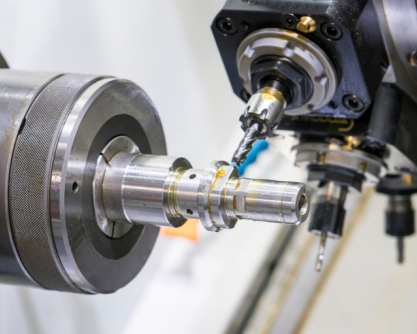

The intricate engravings that adorn watch dials and cases require a level of precision that transcends the capabilities of traditional tools. High precision engraving tools, often using advanced CNC technology, bring micrometric detail to life. Every line, curve, and motif is etched with meticulous accuracy, turning a watch into a wearable work of art.

Crafting Balance Wheels and Escapements

In the world of horology, where the rhythmic oscillation of a balance wheel and the delicate escapement define the accuracy of a timepiece, the significance of high precision tools becomes even more pronounced.

The balance wheel is the heartbeat of a mechanical watch, and achieving the perfect balance is an art mastered by high precision tools. Whether adjusting the weight of the balance wheel or fine-tuning the hairspring, the tools used in this delicate dance must operate with subatomic accuracy. The result is a watch that not only keeps time accurately but also exhibits the mesmerizing grace of a perfectly balanced mechanism.

The escapement, responsible for the controlled release of energy in a mechanical watch, demands meticulous precision. High precision tools come into play when crafting and adjusting the escapement components. The pallet fork and escape wheel, working in concert, rely on the precision of these tools to ensure a smooth and consistent flow of energy, allowing the watch to maintain its accuracy over time.

High Precision Tools in Material Selection and Finishing

Beyond the intricate components of a watch movement, high precision tools play a crucial role in the material selection and finishing processes that contribute to the aesthetic and functional aspects of timepieces.

High precision tools aid watchmakers in working with materials like stainless steel, gold, titanium, and exotic alloys. Whether cutting, shaping, or polishing, these tools ensure that every material used in a timepiece meets the exacting standards of the watchmaker's vision. The result is not just a functional watch but a piece of craftsmanship that reflects the artistry of material mastery.

The finishing touches on a watch, from mirror-polished surfaces to intricate decorations, require the finesse of high precision tools. Be it bevelling, chamfering, or applying perlage, these tools contribute to the exquisite finishing that distinguishes luxury timepieces. Each detail is a testament to the dedication to perfection that defines the watchmaking craft.

Preserving Tradition in a Digital Age

In an era dominated by digital timekeeping devices, the tradition of mechanical watches endures, and high precision tools play a vital role in preserving this legacy.

High precision tools empower artisans to preserve the time-honored traditions of handcrafting mechanical watches. The delicate touch of a skilled watchmaker, guided by precision tools, ensures that each timepiece carries the legacy of centuries-old craftsmanship. This artisanal approach not only adds to the allure of mechanical watches but also pays homage to the artistry of horology.

While rooted in tradition, high precision tools also contribute to the innovation seen in modern watchmaking. From the use of advanced alloys to cutting-edge manufacturing techniques, these tools enable watchmakers to strike a balance between honoring tradition and embracing the advancements that define the industry's future.

In conclusion, high precision tools are the unsung heroes in the realm of watchmaking and horology, contributing to the creation of timepieces that transcend mere functionality to become works of art. As these tools continue to evolve alongside technological advancements, the timeless pursuit of precision and craftsmanship in watchmaking will undoubtedly reach new heights, ensuring that each tick of a mechanical watch remains a triumph of timekeeping precision and artistic mastery.

- Benefits of Custom Rapid Prototyping ServicesMarch 19, 2024In today's fast-moving industrial sector, custom rapid prototyping services have become an important tool for many companies to enhance the competitiveness of their products and accelerate the pac...view

- What Are The Characteristics Of Precision CNC MachiningFebruary 27, 2023First, precision CNC machining process is concentratedCNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, th...view

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Fathom Precision, as a leader in this field, has injected new vitality into the development of the aerospac...view

- Unlocking the Benefits: Urethane Casting Service ExplainedOctober 27, 2023In the world of rapid prototyping and low-volume production, urethane casting has emerged as a versatile and cost-effective method. Urethane casting services offer a wide array of benefits that can re...view

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view