With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and material innovation. fathom Precision, as a leader in the field, contributes to the innovation of the architectural industry by virtue of its superb technology and unique brand advantage.

Enhancing the efficiency and precision of architectural design

In architectural design, prototype machining services can quickly transform designers' concepts into physical models, and Fathom Precision's Prototype machining service, with its high efficiency and accuracy, helps designers verify the feasibility and aesthetic effect of the design before the actual construction, thus greatly improving the design efficiency and accuracy.

Accelerating the building construction process

While traditional building construction methods are often time-consuming and labor-intensive, Fathom Precision's Rapid Tool service is able to quickly produce the required construction tools and molds. This not only shortens construction preparation time, but also improves construction quality and efficiency. At the same time, Plastic Molding and Plastic Mold technology also provides the possibility of rapid molding of construction materials.

Innovative Building Materials and Structures

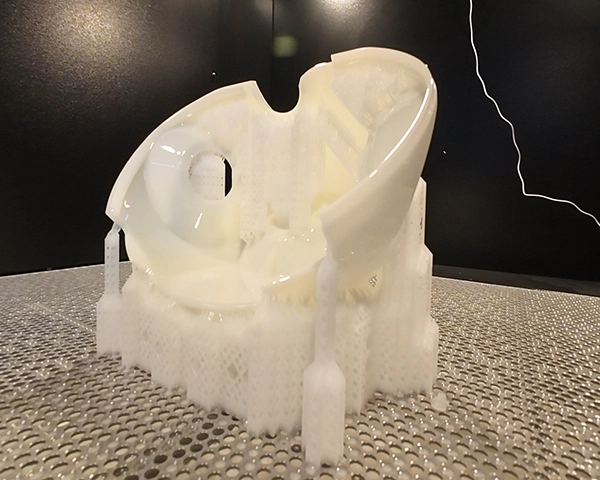

Prototype machining services also play an important role in the research and development and application of building materials, and Fathom Precision's CNC Machining and 3D Print Vacuum Casting technologies are able to produce building components with complex structures and new materials. These innovative materials not only provide excellent performance, but also fulfill architects' pursuit of aesthetics and sustainability.

Promoting sustainable development in the construction industry

Fathom Precision's Insert Mold and Die Casting technologies play an active role in energy saving and resource recycling in the construction industry. Through these technologies, architects are able to design more energy-saving and environmentally friendly buildings, promoting the construction industry to move forward in the direction of sustainable development.

To summarize, the application of prototype machining services in the construction field not only improves design efficiency and construction quality, but also promotes the innovation of building materials and structures. And Fathom Precision, with its unique brand advantage and technical strength, has made significant contributions to the progress and development of the construction industry.

- Automotive Evolution: Enhancing Vehicle Design with Urethane Casting ServicesJanuary 5, 2024The world of automotive design has continuously evolved to meet the demands of consumers seeking high-performance vehicles. In recent years, urethane casting services have emerged as a vital tool for ...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view

- Exploring the Capabilities of 5 Axis CNC MachiningSeptember 1, 20235 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of p...view

- What Are the Advantages of 5 Axis CNC?September 19, 20235 axis CNC machining is an advanced manufacturing process that utilizes five axes of motion to cut and shape materials. This technology is an improvement over the traditional 3 axis machining process,...view

- Beyond 3D Printing: Exploring Precision Prototyping MachiningOctober 27, 2023The world of manufacturing and rapid prototyping has seen significant advancements in recent years. While 3D printing has gained immense popularity for creating prototypes and functional parts, there&...view