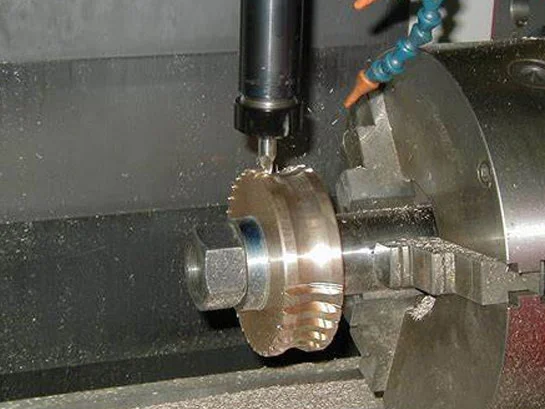

The custom CNC machining service provided also for small metal and plastic parts for prototype and production with high quality and precise products throughput. Small CNC-machined parts are produced by Fathom Precision prototype manufacturing company for a variety of markets and uses. 25 CNC machines are devoted to our prototype machining services of small parts at our plant in China. These machines have work envelopes no larger than 25 inches, and a quality/inspection team using the most advanced metrology technologies supports them. Our knowledgeable CNC machine operators adhere to the most recent quality requirements for the Semiconductor, Military, Medical, and Communication industries. Of course, our CNC prototype machining services for small parts can be upgraded to Precision Mechanical Assemblies or employed in the production of machinery.

The main feature of small CNC part machining is the ability to produce small components with high precision and accuracy. This is achieved through the use of specialized precision toolings and equipment, and advanced programming techniques. Additionally, small CNC part machining can be used with a variety of materials, including metals, plastics, and composites.

As one of the custom CNC machining service, small CNC part machining is used in a wide range of industries, such as electronics, medical devices, and aerospace. In the electronics industry, CNC machining small parts are used in the production of circuit boards and other components. In the medical industry, small CNC parts are used in the production of surgical instruments and implants. In the aerospace industry, small CNC parts are used in the production of aircraft components, such as engine parts and control surfaces.

The advantages of small batch CNC part machining include the ability to produce small components with high precision and accuracy, reduced production times and costs, and improved quality control. Additionally, small CNC machines can be programmed to produce multiple parts simultaneously, which can increase production efficiency and reduce lead times. This process also allows for more efficient use of materials, reducing waste and improving sustainability.

Small-batch CNC machining can work with a wide variety of materials, depending on the specific requirements of the project. Here are some of the most common materials used:

Metals:

Aluminum: It's lightweight, has a good strength-to-weight ratio, and is easy to machine. It's commonly used in the automotive, aerospace, and electronics industries.

Stainless Steel: Known for its corrosion resistance and strength, it's often used in medical devices, food processing equipment, and other high-stress applications.

Brass: Easy to machine and good for parts that require low friction, like gears, locks, and bearings.

Copper: Excellent electrical conductivity makes it ideal for electrical components.

Titanium: It's strong, lightweight, and corrosion-resistant, making it ideal for aerospace and medical applications.

Plastics:

ABS: A common thermoplastic with good impact resistance and toughness.

Polycarbonate: Known for its strength and transparency, it's often used for protective gear and lenses.

PTFE (Teflon): Has excellent chemical resistance and is used in many industrial applications.

Nylon: It's strong, wear-resistant, and flexible, making it ideal for gears and other moving parts.

Acrylic: It's transparent and has excellent weather resistance, making it a common choice for display cases and windows.

Composites:

Carbon Fiber: It's lightweight and has high tensile strength, making it ideal for aerospace and automotive applications.

Fiberglass: It's strong, lightweight, and less expensive than carbon fiber, making it a popular choice for many industries.

CNC machining is used to create small parts for a wide range of applications across various industries. Here are some examples:

Electronics: CNC machining is used to create small parts such as circuit boards, connectors, and casings for electronic devices.

Medical: In the medical industry, CNC machining is used to create small, precise parts for medical devices and equipment. This includes surgical instruments, implants, and components for diagnostic equipment.

Automotive: CNC machining is used to create small parts for vehicles, such as engine components, sensors, and other intricate parts that require high precision.

Aerospace: In the aerospace industry, CNC machining is used to create small, lightweight, and highly durable parts for aircraft and spacecraft.

Defense: The defense industry uses CNC machining to create small parts for weapons, military vehicles, and other defense equipment.

Telecommunications: CNC machining is used to create small parts for telecommunications equipment, such as connectors, housings, and other components.

Consumer Goods: CNC machining is used to create small parts for a wide range of consumer goods, from appliances to toys to personal care products.

Industrial Machinery: CNC machining is used to create small, precise parts for various types of industrial machinery and equipment.

Energy: In the energy sector, CNC machining is used to create small parts for various energy systems, including wind turbines, solar panels, and nuclear reactors.