Providing China precision plastic injection tooling services included project management with DFM, mold flow analysis, tool design, high precision tool supply and manufacturing, mold trials, parts manufacture, quality inspection, and delivery under our global services strategy.

We, as a China plastic injection mold tooling manufacturer, provide tooling services involving prototype tools, rapid tools, high precision machine tools, as well as export tools to copy with customer's various plans of precision machining and manufacturing.

The prototype machining services and rapid tooling services provide a fast turnovered lead time down to 7 days completion, Integrated with our injection molding services, the fastest lead time is 10 days for production for prototyping projects and low volume demand.

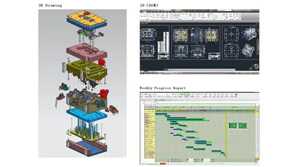

Tooling design includes the 3D model and 2D BOM for customer review and approval as well as tool build scheduling for export tooling

The service of mold flow analysis allowing customer to validate any molding issues for the part design that giving the engineering benefit to optimize the part design with molding advantage

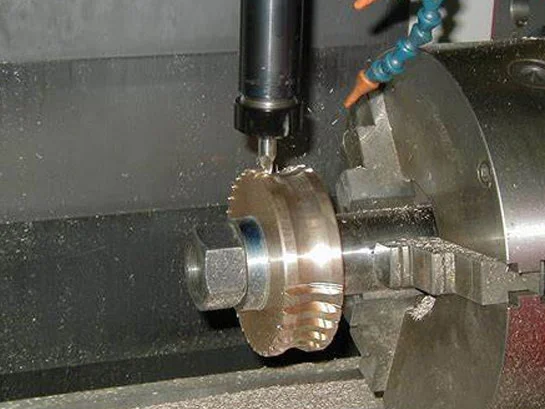

Prototype and Rapid Tooling

This precision tool and manufacturing process involves the creation of a preliminary model or sample, allowing precision toolings manufacturers to test and refine a design before moving into full-scale production. Rapid tooling, in particular, is a fast and cost-effective way to produce prototypes for testing and validation.

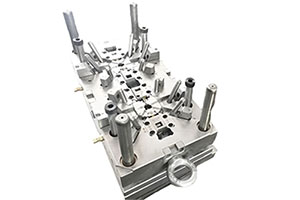

Production Tooling

The process of creating durable and high precision machine tools and dies for mass production. These high precision tools are designed to withstand the rigors of long production runs, ensuring consistent quality and efficiency throughout the manufacturing process.

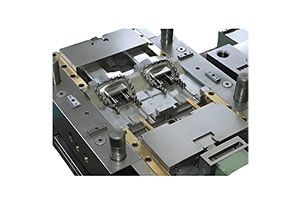

Export Tooling

This involves the production of tools and dies for manufacturers located in other countries. Export tooling requires a deep understanding of international standards and specifications to ensure the tools produced by precision tooling supplier meet the requirements of the overseas manufacturer.

In order to provide the best service to our customers, Fathom Precision has honed its skills in creating custom molds, dies, and tools. These are specifically designed to manufacture your products and components to the highest standards. Our expert teams are dedicated to supporting your internal tooling needs. We possess the necessary skills and highly specialized technologies to design, fabricate, and maintain the complex tools used to produce your devices and components.

We pride ourselves on our in-house tooling capabilities, which are state-of-the-art. These include the ability to design, build, and optimize:

Injection Molds (including multi-shot and insert molds)

Manufacturing and Assembly Fixtures

Stamping Dies (progressive, transfer, single station, and modular tooling)

Custom urethane casting service

Our aim is to ensure that your products are produced with precision and quality, meeting all your specifications and requirements.

Precision tool manufacturing serves a wide range of industries, including but not limited to:

Automotive: Precision tools are used to manufacture various automotive parts, including engine components, body parts, and interior components.

Aerospace: This industry requires high-precision tools for the production of aircraft components, including engines, structural parts, and avionics.

Medical: Precision tools are used in the manufacture of medical devices and equipment, such as surgical instruments, implants, and diagnostic equipment.

Electronics: Precision tools are essential in the production of various electronic components and devices, including circuit boards, semiconductors, and sensors.

Defense: The defense industry relies on precision tools for the production of various military equipment and components, including weapons, vehicles, and protective gear.

Energy: Precision tools are used in the manufacture of components for various energy systems, including wind turbines, solar panels, and nuclear reactors.

Consumer Goods: Precision tools are used in the production of a wide range of consumer goods, from appliances to toys to personal care products.

Construction: Precision tools are used in the manufacture of various construction equipment and materials.

Telecommunications: Precision tools are used in the manufacture of various telecommunications equipment, including network infrastructure and mobile devices.

Oil and Gas: Precision tools are used in the manufacture of various equipment used in the oil and gas industry, including drilling equipment and pipeline components.